Lean Six Sigma, Prince2, Agile, Lean are all approaches to organisation improvement. They are all different, but have one thing in common. They are all structured approaches. In other words they are organised, planned in advance and have systematic ways of doing things.

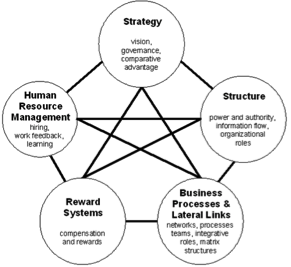

Jay Galbraith developed a "Star Model™" framework for analysing the structure of organisations. The Star Model™ framework consists of a series of areas that can influence employee behaviour. There are five areas: strategy, structure; processes, rewards and people.

Addressing the five areas of the Star Model™ allows organisations to ensure that they consider all aspects of “structure” fully.

Buy why is there a need to have organisation improvement “structured”, and does it actually work? Opponents will argue that Toyota, the founders of the Lean approach, did not start out with a structured approach, Taichi Ohno himself states that in the beginning “all we were trying to do was to reduce the timeline”. 2 There was no set method, no emphasis on employee involvement, no making of the business case.

Still others will argue that structure is fine for large organisations, but smaller organisations, which make up over 95% of all organisation and employ between 60 and 70% of all people employed3, “can’t afford the time and resource to structure things”.

So if smaller organisations don’t want or need to structure, and Toyota did not start off with a structured approach, surely the majority of us should adopt the same approach, and over time we will achieve the same results won’t we?

Well the simple answer is maybe, but probably not. So why is this?

Firstly, for every Toyota that started out with a goal of becoming a world leading company and improving every aspect of their organisation continually over many years there are a thousand organisations that have not been able to do so. One isolated example (Toyota) does not make this a sound strategy for the rest of us to follow. Today of course Toyota has a very structured approach to the improvement of their organisation.

Secondly, the world has changed since the 1950’s when Taichi Ohno first started reducing the timeline. Historically organisations were managed using a command and control approach, the person at the top would set the goals, make the decisions, and then cascade that decision down through the organisation. Today, almost everyone has access to the internet, and there are almost daily changes in technology. Information availability and speed of change means command and control processes no longer work. If you have ever googled for a search term, you will find no doubt thousands if not millions of sites with results that match your search query. It is impossible for one or even a small number of people at the top of the organisation to know everything, be in touch with everything and make every decision. It is too slow for the people at the top to set goals, make every decision and cascade the decision down through the organisation.

The average person has more computing power in their mobile phone than was used on the first lunar landing, the total knowledge of the human race doubles every four years. In that environment, decision making power has to be devolved through the organisation, and hence there is a need for structure.

Thirdly, ironically the “leaning out” of organisations means operational staff have little time to carry out data analysis within their normal roles, and unless there is some driver to make it happen they won’t do it, preferring instead to concentrate on areas where they are being measured and rewarded. Unless the measures and rewards change to reflect a need to improve then it won’t happen. Coming back to the idea of smaller organisations not requiring formal structure, it is true that very small organisations, maybe those under 20 people, can be managed effectively with little or no structure, but research tells us that if you have more than 20 people, you will need to provide structure to effectively manage any aspect of an organisation, including improvement.

Fourthly, in most organisations, processes in use have developed over time and are often reliant on computer systems. Any changes require financial justification before they can be considered; it is not possible for the processes to be changed without this. The gathering of the information required to make the business case for the change is not something that can be done without allocating resource and time, which often requires the backing of a sponsor to kick things off.

Finally, we can learn from others. Motorola, GE and many others have demonstrated that the structured approach works. In 1978 Motorola sold a TV business, and as a direct result in 1981 started a major training programme across the organization. 6 years later the programme was developed to include specific targets and methodologies. In 1988 they won the prestigious Baldrige award, and in the early 1990’s the Motorola share price outperformed the rest of the US market by a factor of 4:1.

GE started using Six Sigma approaches in 1995 adopting the methodologies and the black belt infrastructure. GE applied Six Sigma to all aspects of their business, not just Manufacturing and achieved $1Bn savings within 5 yrs & $10Bn in 10 yrs.

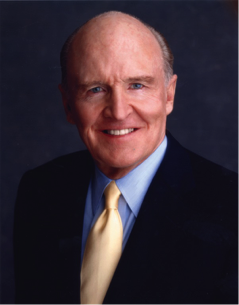

Jack Welch, the charismatic leader of GE during that period, made no secret of the fact that Six Sigma played a major part in the company’s success. Jack Welch was subsequently named manager of the century, and in 2009 GE was listed by Forbes as the World’s largest organisation.

So what is structured improvement trying to achieve? At the beginning of the article, we mentioned being organised, planning in advance and having a systematic ways of doing things. Edward de Bono defined a problem as the difference between what one has and what one wants. In organisation terms these are the performance gaps, or strategic gaps that exist. If we define organisation improvement as addressing the gaps between what we have and what we want, then structured improvement is an organised, systematic and planned approach to achieving the strategic goals of the organisation.

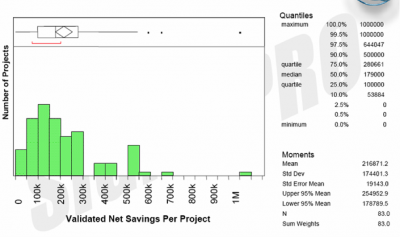

A study done in 2000 of over 3,000 Six Sigma projects by Mikel Harry found that the average value of a project was approximately £100,000. A typical Black Belt should be running 3-4 projects per year, which equates to an annual saving of over £300,000 for each belt. A study by the UK DTI (now the Department for Business, Innovation & Skills) of 500 lean projects showed the average realised value to be £151,000 per project. So, Lean and Six Sigma approaches are proven at strategic organisation level and also at individual project level to add significant value.

Lean Six Sigma addresses the need for structure by having clearly defined methodologies and tools (DMAIC), clearly defined performance measurement standards (Sigma) and clearly defined roles (belts, champions) amongst other things. Lean Six Sigma is a comprehensive approach to structured organisation improvement.

In summary, for most organisations today there is a need to have a structured approach to organisation improvement. It will not otherwise happen. Lean Six Sigma can be used as the basis of such a structured approach, with the knowledge that it has helped many other organisations to achieve dramatic improvements in financial performance, and helped them achieve their strategic goals.

1 Designing Organizations: An Executive Guide to Strategy, Structure, and Process. 2001, Jay R. Galbraith

2 Toyota Production System, Taichi Ohno, 1988, Productivity press

3 OECD policy brief, 2000, Small and Medium-sized Enterprises